Before the PTFE layer is punctured, the chemical compatibility properties of the PTFE will determine the solvent compatibility. It is only after the closure is punctured that the septa material will determine compatibility (see table below). Phenomenex recommends "once and done "with all caps and vials.

Jan 6, 2022 · CSTDs and related vial adaptors must also be chemically compatible with the drug formulation. Some chemical compatibility considerations, regarding the stability of the adaptor to the drug formulation and the leachability of the adaptor’s composition into the drug product, are discussed by West’s Amy Kim and Heike Kofler.

The ability of plastic materials to resist chemical attack and damage is dependent also on temperature, length of exposure to the chemical, and added stresses such as centrifugation. For more detailed chemical resistance ratings for Nalgene products and materials, please consult the resources referenced at the bottom of this page.

Choosing the right septa and closures for your analysis is critical to ensure chemical compatibility with your sample and solvents and protect sample integrity and prevent contamination. Screw and snap caps are usually made of plastic, mostly polypropylene (PP) or polyethylene (PE), whereas seals for crimp-top vials are made from aluminum.

Ideal for use with reactive and corrosive chemicals. The melting point of PTFE 1 is 600°K (327°C / 620°F) Low temperature: maintains high strength, toughness and self-lubrication as low as 5°K (-268°C /-450°F) and good flexibility at 194°K (-79°C / -110°F) NOT compatible with certain alkali metals and fluorinating agents such as xenon

The melting point of polypropylene is 160°C / 320°F) Low temperature threshold: polypropylene becomes brittle below 0°C. NOT compatible with strong oxidants. Polypropylene Chemical Compatibility Chart: Check the chemical compatibility of Polypropylene with various chemicals, solvents, alcohols and other products. Shop Polypropylene.

Jun 21, 2018 · The glass vial offers several advantages over the plastic vial. For instance , it provides compression strength, considerable chemical inertness, impermeability to gas, resistance to heat, and transparency for product visibility. In contrast, the plastic vial lacks all these benefits of the glass vial.

• Bi-layer: Made from two distinct materials – one to create a barrier (usually PTFE) and one to allow for resealing (usually silicone) • Tri-layer (also known as a sandwich septum): Still made from two distinct materials – usually silicone surrounded on both sides by PTFE Table 1. Septa chemical compatibility.

Chemical & Material Compatibility Database This quick and easy tool allows you to select from nearly 600 chemicals to see how they effect 40+ materials used in fluid handling systems. Use the drop downs below to select a Chemical or Material and compare against the whole the database (ALL) or a specific requirement to your application.

CHEMICAL TO CHEMICAL. Use dropdowns below to select a Chemical, and compare against ALL MATERIALS or any specific material. 1. CHEMICAL. 2. MATERIAL. VIEW COMPATIBILITY.

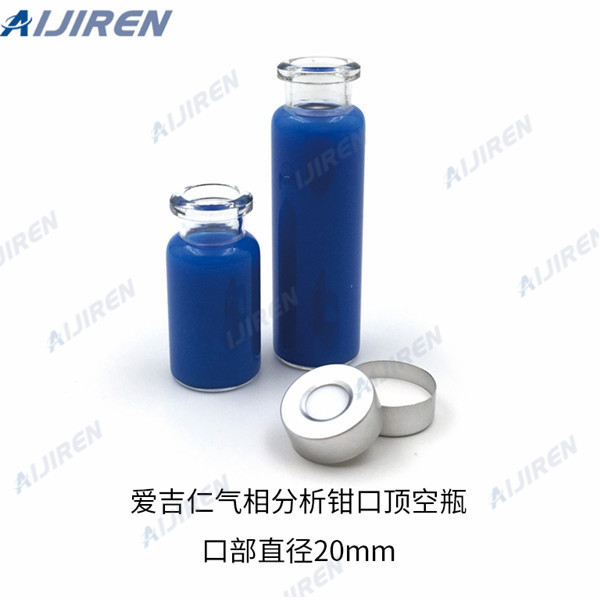

Use our Chemical Resistance and Septa Solvent Compatibility Sections for more details Contents Choosing the right septa chart 2 Septa selection guide Septa material: General Chromatography vials 3 Septa material: 20 mm headspace septa 4 Temperature stability chart 4 Seal properties 5 Seal selection (for headspace and sample

Jun 20, 2018 · Polymeric materials offer light weight, shatter resistance, greater formability, tighter tolerances, strong barrier, and chemical compatibility. As a result, plastic packaging is gaining ground with global demand for plastic parenteral vials forecast to grow 7.7% per year to more than $1.6 billion (13.1 billion units) in 2021 (2).

High density polyethylene is used to make Nalgene bottles, carboys, and other items where impact strength and long-term chemical compatibility are key requirements. HDPE is lower cost than many labware materials making it a good choice where economic savings and product value are appreciated. A wide variety of Nalgene bottles are made from HDPE.

Chemical Compatibility of Disposable Plastic Centrifuge Tubes The mechanical strength, flexibility, color, weight, and dimensional stability of all plastic centrifuge tubes are affected to varying degrees by the chemicals with which they come in contact. Specific operating conditions, especially

Apr 26, 2022 · From a compatibility standpoint, it is important to recognize that the fluid links virtually every component as it circulates through the liquid cooling system. Table 1 provides a brief overview of a number of fluids typically used in cooling electronics. The first step in selecting a coolant is to consider operating and storage temperatures.